Pioneer of graphite products

With the pioneering spirit of "creating something that can't be found anywhere else", we have developed innovative technologies such as the world's first mass production of "large isotropic graphite". Starting from the production of carbon brushes, our company now supports a wide range of products from home appliances, automobiles and industrial machinery to semiconductors and aerospace, all of which are familiar to the global market. We would like to introduce you to our innovative technologies that continue to explore the ever-expanding possibilities of carbon.

Catalogs and brochures are available for free download at the bottom of this page.

If you have any questions or concerns, please use the Toyo Tanso Product Inquiry Form.

《Topics》

Features of Graphite|Low friction and wear without lubricants Frictional Properties

Materials and parts wear out due to repeated contact and friction. Lubricants are used to reduce the wear. However, lubricants cannot be used in harsh environments such as high temperatures and vacuums because they degrade or evaporate. Graphite is used in environments where such lubricants cannot be used. Graphite has a layered crystal structure, high self-lubricity, and a low coefficient of friction, making it resistant to friction and wear. Because of these features, graphite is used in a wide range of industrial fields that require frictional properties.

In addition, graphite can be treated in various ways to improve its inherent functions or add new functions. One of the treatment method is the “impregnation treatment". Impregnation treatment is a treatment in which a liquid is soaked into the microscopic holes of the material. Toyo Tanso offers a wide range of impregnation treatments including inorganic impregnation, resin impregnation, and metal impregnation.

As shown in the video, graphite has a porous structure with holes. Thanks to its porous structure, impregnation treatment is possible. Impregnation treatment inhibits oxidation and wear, improves strength and conductivity, and can be used for fluid sealing and other applications where graphite as is cannot be used.

Toyo Tanso's Mechanical Carbon products

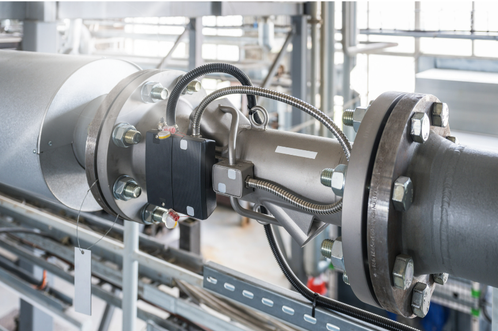

Taking advantage of graphite's characteristics of self-lubrication, chemical resistance, and heat resistance, it is used as a sliding material in high-temperature atmospheres where metals cannot be used, in chemical solutions, and in fields where lubricants cannot be used.

Impregnated products are used in bearings, seal rings, packings, vanes, rotors and so on.

In addition to impregnation treatment, Toyo Tanso has other technologies to strengthen graphite and can respond to a variety of requests. Please contact us if you have any problems.

Free Material Download

Our new catalog is now available.

If you do not have it yet, you can download it here.

More information is available on the product website.

WEB Inquiry Form

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。